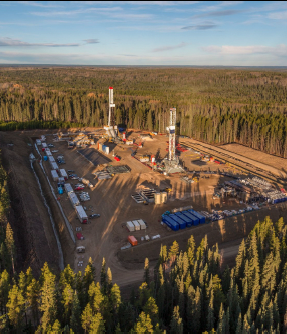

Hydraulic Fracturing

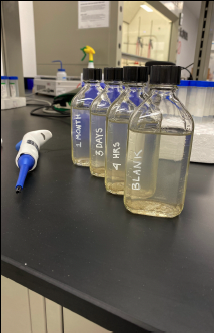

Where there is water, there are microbes — from drilling mud, stimulation fluids, produced water, proppant, finished fuels, in the reservoir and in pipelines — and if left untreated, they can cause fouling, souring, corrosion and create costly setbacks.

For 30 years, OSP has built a reputation as the go-to microbial expert specializing in microbial identification, surveillance and mitigation.

We support clients in understanding their microbial environment so they can protect their assets and prevent future challenges.